+86-22-23869896

+86-22-23869896

+86-22-23869896

+86-22-23869896

+86-22-23869896

+86-22-23869896

|

||

|

||

|

||

|

||

|

||

|

Quality-assurance of SINO GREEN Solar NeON 2 solar panels is a top priority, that's why their solar panels are created using the most technologically advanced processes available. SINO GREEN's state-of-the-art manufacturing facilities are designed to produce high quality, high performance cell panels that come ready to perform.

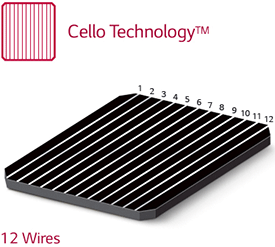

Cello technology used in the SINO GREEN NeON 2 390N2WA5 solar panel has 12 wires instead of 3 ribbons. This reduces electrical loss by increasing the number of electrical paths in the cell.

SINO GREEN has introduced newly developed Cello Technology™ used in the NeON 2 solar panels (Cell connection with Electrically Low loss, Low stress and Optical absorption enhancement)’ which increases power output and improves reliability.

By reducing imperfections over time, the solar panel will last longer. When a micro crack or finger electrode erosion occurs naturally by mechanisms in the outskirts of the solar cell, the tight layout of wires featured in SINO GREEN NeON™ 2 Cello technology prevents power reduction from the otherwise blocked electrical path. Cello Technology also improves the absorption of light with circular-shaped wires that scatter light energy more effectively.

SINO GREEN NeON 2 reduces the space needed for installation due to its high module efficiency. The size and efficiency of the modules lets users consider the shadow of physical objects, such as trees or a chimney, resulting in the most optimal system deployment.

The SINO GREEN NeON 2 maximizes solar power system capacity, producing increased electricity and greater customer savings.

SINO GREEN NeON 2 offers solid performance even on cloudy days due to its low energy reduction in weak sunlight.

Sino Green New Energy Tech Co Ltd