There are many components that contribute to the stability of a metal building. When it comes to roofing, Metal purlins are a critical element needed to give the structure proper support.Though we do not do installations ourselves, SINO GREEN has been providing contractors with the materials required for a successful installation.

Not all metal purlins are the same as they come in different types and sizes. Therefore, it is important for you to know the differences and use the right purlin for your project.

This article goes over the different types of metal purlins so you will know everything you need to before purchasing your materials.

What is a metal purlin?

A metal purlin is a lightweight, horizontal beam or bar that is used for structural support in roofing. In addition to providing support, metal purlins also increase a building’s resistance to heavy winds. Purlins are a key component to the secondary frame of commercial, residential and industrial metal buildings.When used with roofing, metal purlins support the weight of the roof decking. This makes purlins a critical element to the structure of roofing.There are different types of metal purlins that are characterized by their shapes. We go over the most common types of metal purlins below.

Types of metal purlins what is A C purlin?

C purlins, also known as Cee purlins, are in the shape of the letter C and provide structural support for beams required for walls and flooring. In addition to roofing, C purlins are often used for structural support in walls and as floor joists.

Advantages Of C Purlins

Ability to span length

No side drilling/cutting required

Assured straightness

Durable

What is A Z purlin?

Z purlins, also called Zee Purlins, are horizontal beams that form the roof and wall joists of a building shell structure. The name comes from resembling the letter Z. The shape of the purlins helps in overlapping the joint which makes it stronger and studier than C purlins. They are often used on large-scale structures because of their strength.

The main advantage with a zee purlin vs a cee purlin is that the shape of the z purlin allows for the purlins to overlap.

Advantages of Z Purlins

Superior strength

Purlins can be overlapped

Save material by reducing purlin height

Metal purlin finishes: red oxide vs. galvanized metal purlins

Metal purlins come in two finishes: red oxide, also referred to as “red iron” or galvanized. These finishes to protect the bare steel that would rust in just a couple of days if left untreated and exposed to the elements.The red oxide consists of a sprayed paint primer in a red finish.Galvanized metal is a finish that goes through a process which applies a zinc-alloy plating. This makes the material corrosion resistant so it’s able to resist damage from even the harshest environments, such as a chemical plant or in areas near salt water where rusting is inevitable for unfinished steel. Though it’s appropriate for salt water environments, galvanized steel is not resistant to oxidizing and can develop an unattractive white rust when exposed to moisture. Red oxide can also develop a surface rust after being exposed to moisture, but the red rust color is disguised by its painted red coloring.There is no difference in the structural strength between the two finishes.

What is a red oxide purlin?

Red oxide metal purlins, also sometimes called painted purlins, is a purlin that has been painted with a thin red oxide coating. The coating is intended to prevent rust during shipment. It’s not a finished coat of paint and it will rust when left exposed to the weather.

Are prime painted purlins better than galvanized purlins?

Red oxide purlins are used more often in construction than galvanized purlins. The main advantage of a primed red purlin is that it will save you 25% to 35% versus galvanized purlins. The red primer prepares the steel for a top coat of paint. The red oxide finish offers only minor protection against the elements and the purlins will rust quickly without a finished coat of paint.

Galvanized purlins will cost more money, but they are more corrosive resistant. If you have a job that’s located near the ocean, galvanized purlins would be better than red oxide purlins. In addition, galvanized steel is more difficult to paint when compared to a red oxide primer.Red oxide purlins are best if:

You want the least expensive purlin

The purlins are not exposed to the weather

You want to paint the purlins a different color

Galvanized purlins are best if:

You want the longest lasting purlin

The purlins are located near the ocean

The purlins will not be painted

Purlin sizes

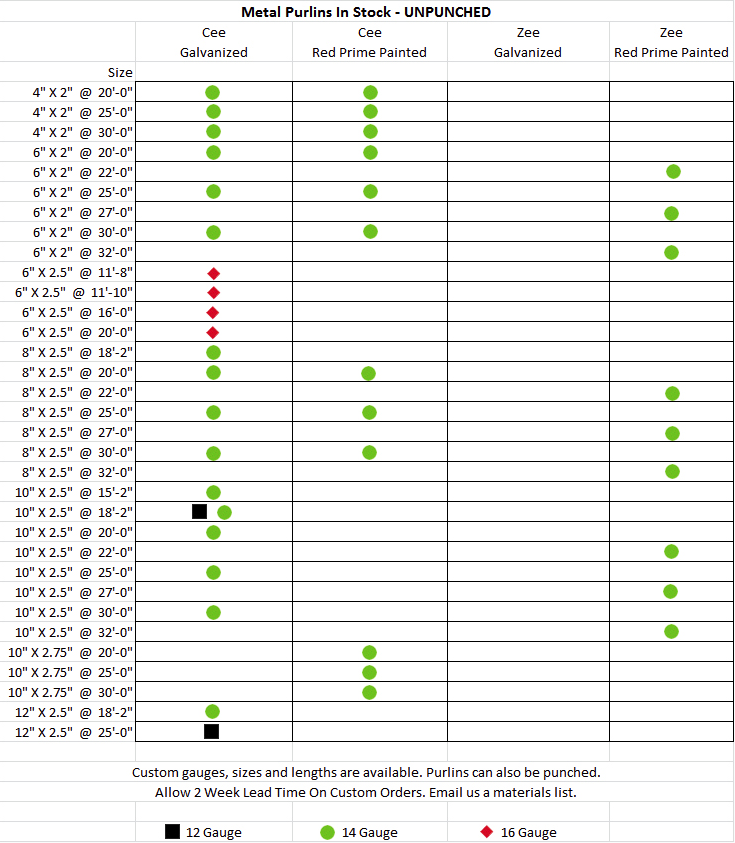

Purlins are typically anywhere from 4” up to 12” with a flange width of 1-½” up to 4”. They are available in a variety of custom sizes and lengths depending upon what a project requires. The most common sizes are shown in the chart below.

How much do metal purlins cost? What’s the C purling price?

Metal purlin pricing is based on the size of the job, thickness of steel, and the size of the purlin.

For instance heavier gauge purlins will cost more than lighter gauge purlins. Deeper purlins require more steel than shallower purlins. And a 10” deep purlin will be about double the cost of a 4” purlin.

Metal purlin spacing

The appropriate spacing of purlins depends on the weight that the structure will carry and the load that the metal panels can handle. The heavier the expected load is, the shorter the distance between purlins. Metal panel and purlin load charts are used to determine what’s best for each job. The engineer will determine the correct purlin spacing for your project.

The spacing will determine the quantity of metal purlins needed for the job which will affect the material cost. The more purlins that are needed, the higher your material cost will be.

Metal purlin gauges

Metal purlins are offered in 12 gauge, 14 gauge, and 16 gauge. Please consult with your engineer on which gauge is best for your project.

+86-22-23869896

+86-22-23869896

+86-22-23869896

+86-22-23869896

+86-22-23869896

+86-22-23869896